Superior quality Concria™ Trowel Hard Nano Silica densifier will be added to dry

shake hardener surface during floating or finishing with blades. You don’t need to

apply any silicates/densifiers later! Trowel Hard is a huge time saver for you. Why

should you go to the job site many times if you can do it all at once?

Professionals need pro products. Right? When using Trowel Hard you can be proud

of the end result. Finnishing can done better as nano silica lubricates surface

during the finishing for more smooth, shiny and denser surface. Product provides

a substantial improvement in abrasion resistance and will significantly improve the

durability of the surface.

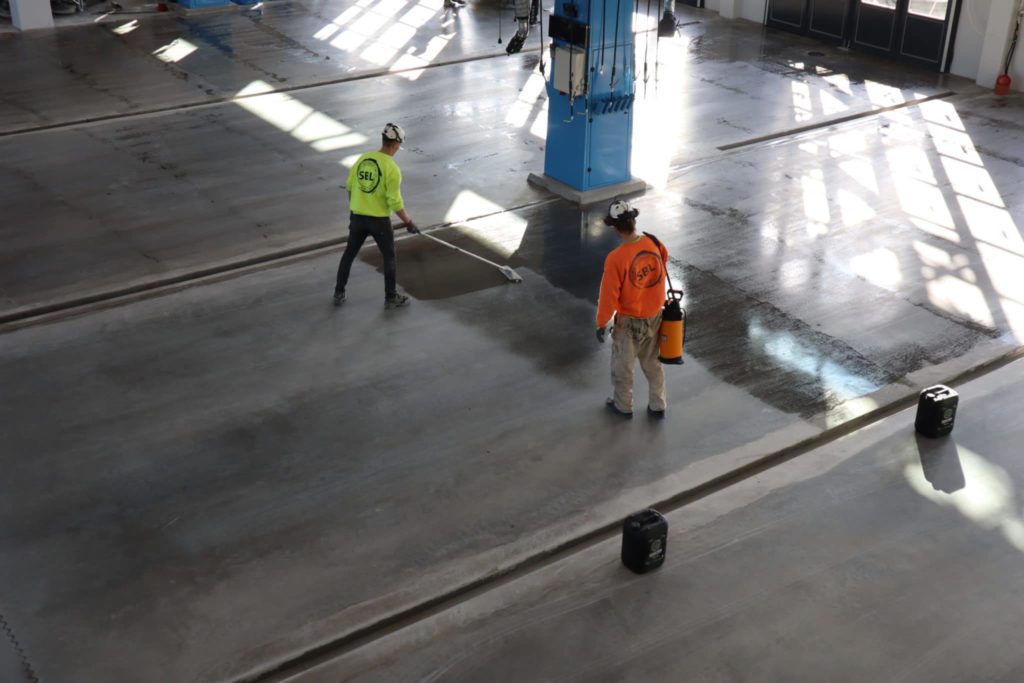

Concria™ Trowel Hard delivers virtually pure silica in nanoparticles small enough to penetrate dry shake pore structure. In the pores, it reacts and creates new calcium silicate hydrate (CSH) that bonds to the existing CSH. It also bonds directly to other silica, including itself. When applied to dry shake hardened surface, it reacts, bonds and then uses bonded silica as a platform for additional bonding. Silicate densifiers (lithium, sodium, potassium etc.) do not do this and can’t be used for fresh dry shake surface like Trowel hard. When Trowel hard is sprayed into the dry shake hardener surface during troweling, it increases the efficiency of cement hydration and this chemical reaction hardens dry shake surface layer completely.

The surface which is treated with Trowel Hard during the floating and finishing with blades, doesn’t need any silicate (Lithium, Sodium, Potassium) treatment later. This is huge time saver as the contractor doesn’t need to go back to job site anymore to apply other densifiers. In the polishing projects contractor doesn’t need to apply ANY densifiers between the polishing/grinding steps as dry shake hardener is densified during the placement. If grinding/polishing is specified to the project, you don’t need to wait 28 days like with normal concrete surface, When Trowel Hard is used together with dry shake hardener the polishing can start already after 7 days as surface has very high compression strength

(56Mpa/8100psi)

Have you ever faced problems at job site with high heat, wind, sun or low humidity conditions? No need for risk taking anymore and spraying water during the finishing which can be detrimental to the dry shake hardener performance. ”Blessing” the dry shake hardener with water weakens the surface and the added water gets encapsulated in microscopic pores in the hardening surface, later evaporating to leave behind voids that make the dry shake hardener surface less dense and strong. Trowel Hard increases cream, making for easier, better finishing and extended workable time under adverse conditions and making surface much more durable than finishing with water. According to water retention efficiency test, Trowel Hard slow evaporation nearly 20% and protecting the dry shake hardener from a range of moisture loss-related defects like delamination, plastic shrinkage, map-cracking, and other surface defects.

After grinding both areas “open” there is no plastic shrinkage or aggregates pop-outs on area which was treated with Trowel Hard

Without Trowel Hard

With Trowel Hard

Concria™ Polish Hard XL is Ultimate Nano Silica Densifier, hardener and dust proofer. Concria™ Polish Hard XL penetrates deep into concrete surfaces and chemically reacts with the concrete matrix and produce an extremely dense and durable concrete floor. Using Concria™ Polish Hard together with grinding and polishing systems you will receive higher gloss and maximum DOI readings.

Concria™ SHIELD is a water based penetrating sealer and it provides maximal water repellent (hydrophobic) waterproofing and improve chemical resistance for concrete. Shield penetrates deep into capillaries, micro-cracks and pores without forming a sealed film.A reaction then takes place between salts and minerals to form a very hard calcium silicate hydride. This results in a crystalline structure that stops the transport of water but lets vapours pass through (diffusion). Because the protection is deeply seated, it is insensitive to external influences such as abrasion and impacts. Shield leaves no topical film on the surface and will wear away only if the substrate itself wears away.