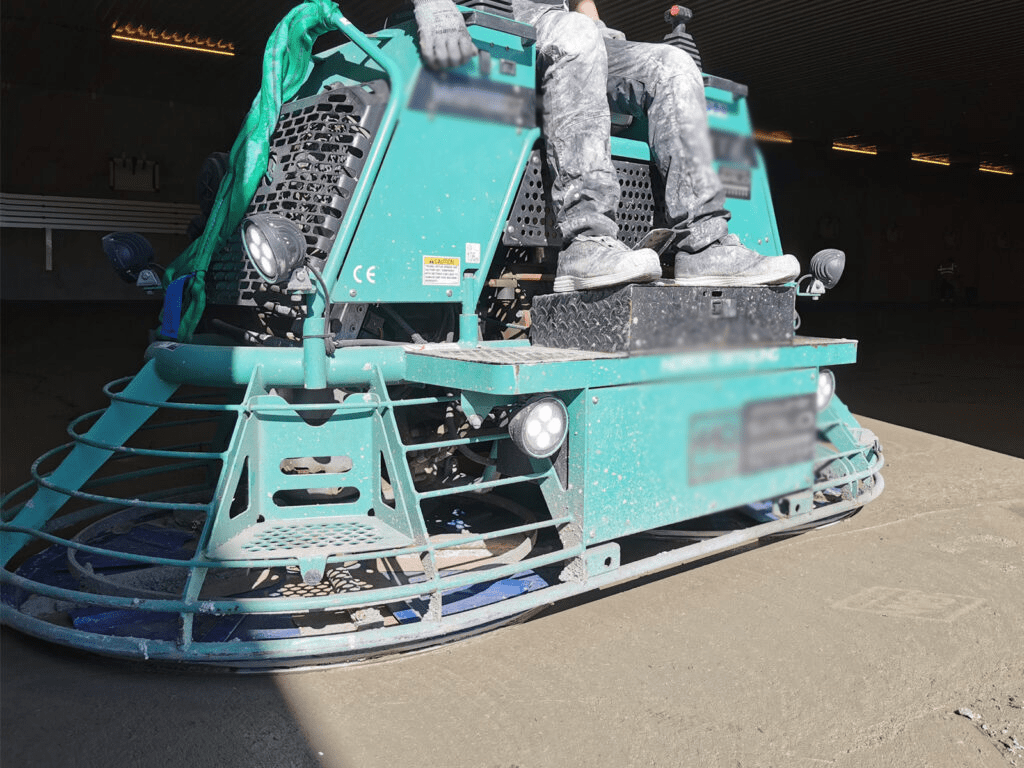

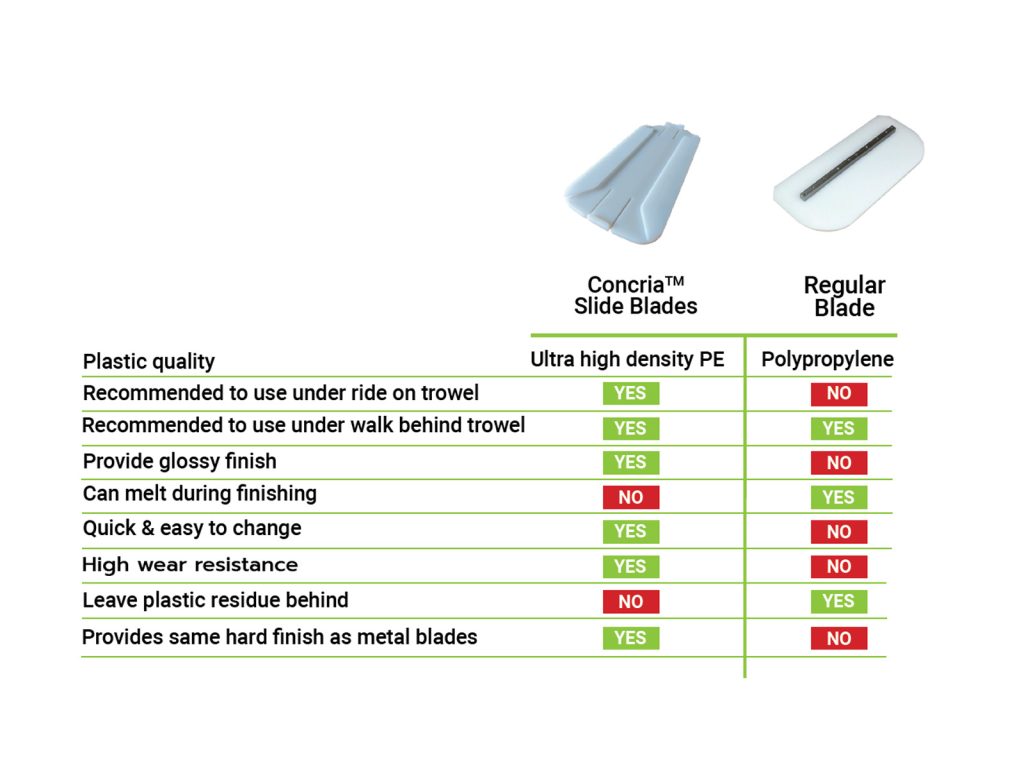

Time plays a significant role in the concrete finishing. It takes 30-60 minutes to change standard blades, but slide blades can be changed in just few seconds.

Longevity, quick to chance and better price per square foot equalizes to the Slide Blades becoming an everyday finishing blade. Slide Blades consumption is over 200,000 sq ft when used after combination/Finishing blades.

Plastic or teflon blades have specified for long time for all decorative concrete projects such as stain, dye, shake on, integral pigments, polished etc. Burnished steel trowel finish increases the potential for mottling and difficulty in uniformly polishing the slab. Slide Blades totally eliminates the risk of leaving dark burnish marks while power troweling concrete or dry shake hardener floors.

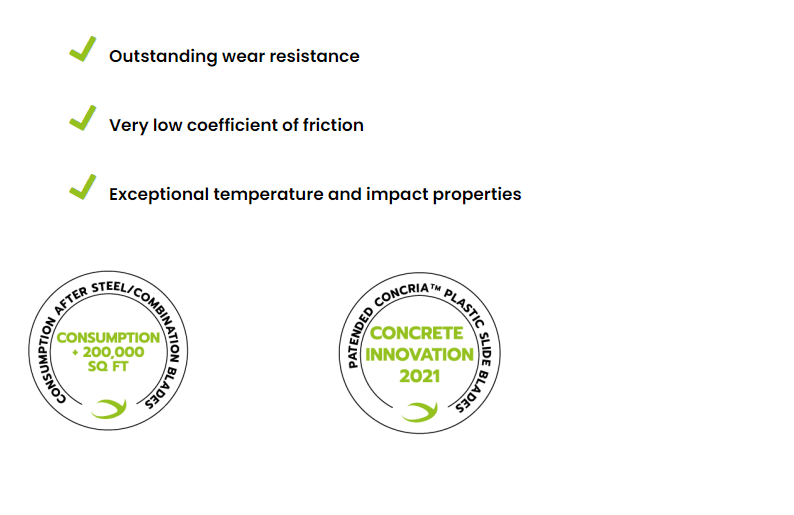

Slide Blades are made of hardest quality plastic and provide outstanding wear resistance, very low coefficient of friction, and exceptional temperature and impact properties. Slide Blades provides as hard and glossy finish than standard metal finishing blades.

10”/ 250 mm for 24” walk behind

14”/ 300 mm for 36” ride on

18″/ 400 mm for 48″ ride on

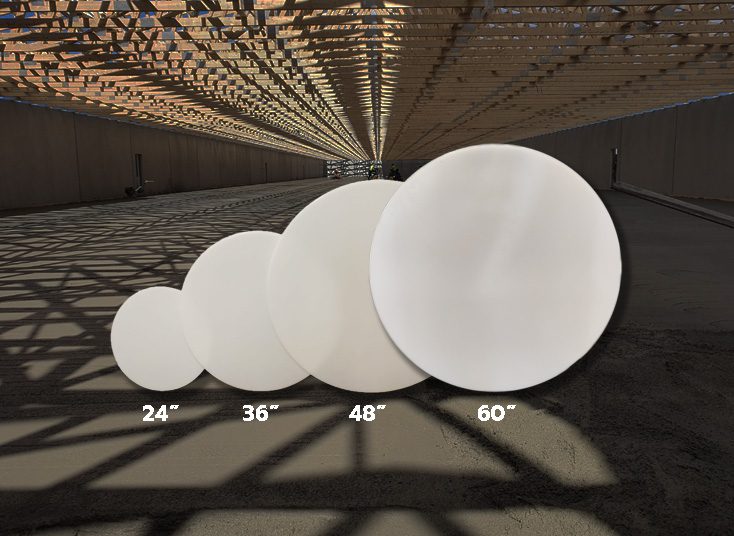

Concria™ Plastic Floating Pans remain today the finisher’s choice when the

high FF Numbers (Floor Flatness) are specified on concrete floors and when

an aesthetic uniform surface is needed. Plastic pans are attached to standard

steel pans easily and fast with a patented velcro fastener system

Thanks to the patented Concria™ Hook & Loop Fastener system, you can attach Concria™ plastic pans over your standard metal pans with Hook & Loop Fasteners. You can quickly change plastic pans to new ones. Plastic pans are available in all standard power trowel sizes from 24” edger up to 60” ride-on trowel pans.

Concria™ Plastic pans composite material provides more outstanding durability than steel and is often cheaper per sq ft than metal pans.

Smoother and uniformly finished surface

Plastic pans bring fewer aggregates on top while floating and minimize aggregates popouts and reduce the chance of surface delamination. Plastic pans eliminate the risk of leaving burn marks and create a more uniform colour surface than steel pan.

Denser slab with acoustic pressure

Concria™ Plastic float pans have an acoustic impedance (ratio of the acoustic pressure) that matches the concrete, thereby imparting its energy into the concrete mass, which causing the concrete to set from the bottom of the slab to the top while maintaining an open surface to allow bleed water to escape during finishing.

Higher FF numbers

Steel pans dig deeper than plastic pans and move more surface mortar/cream, making the floor less flat. With plastic float pans, you also minimize the risk of troughing better than with steel pans if the concrete is too soft or if you hit a wet spot. Plastic provides an easier transition from wet to dry areas when floating

Faster Finishing time

Concria™ Plastic float pans provide a faster finish time as plastic doesn’t dig deep as steel, and you can start a little bit earlier with plastic pans.